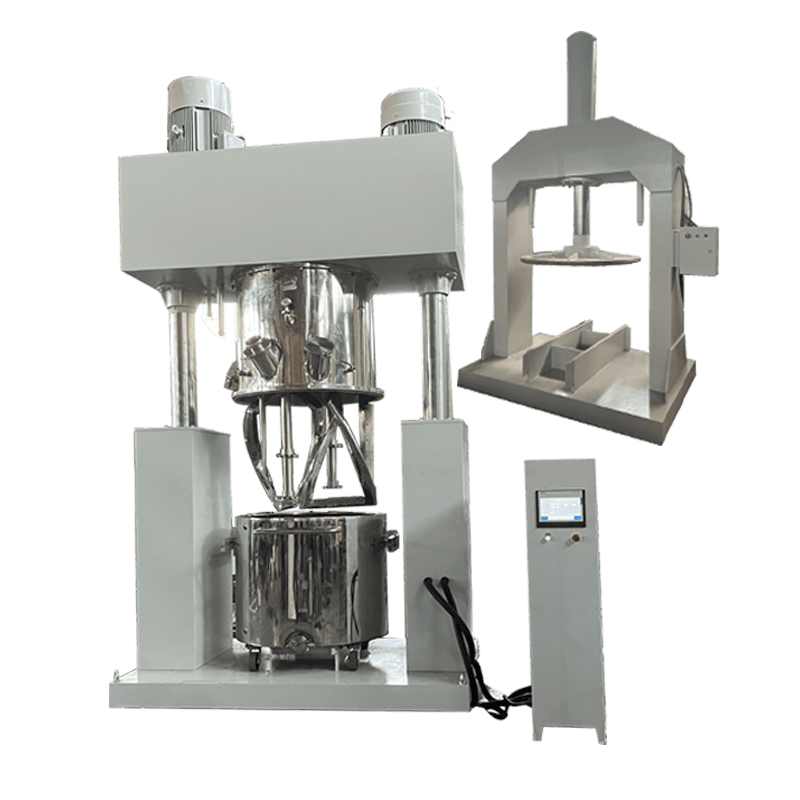

Large Scale Industry Double Planetary Mixer

Orisun’s double planetary mixer offers cutting-edge mixing technology, good safety performance, and customization selections for top product quality and high productivity. Orisun has been committed to the development of double planetary mixers, after nearly 20 years of practical experience and continuous innovation, this advanced equipment provides excellent solutions for professionals in various industries through innovative technology and excellent performance.

Features:

Suitable for adhesive, sealant, MS polymer, Lithuim Battery slurry, solder paste with viscosity 10,0000~1,000,000cps.

Working capacity from 300L 400L 500L 1000L 2000L 3000L .

Extreme vacuum up to -0.1 MPA for high efficiency of defoaming.

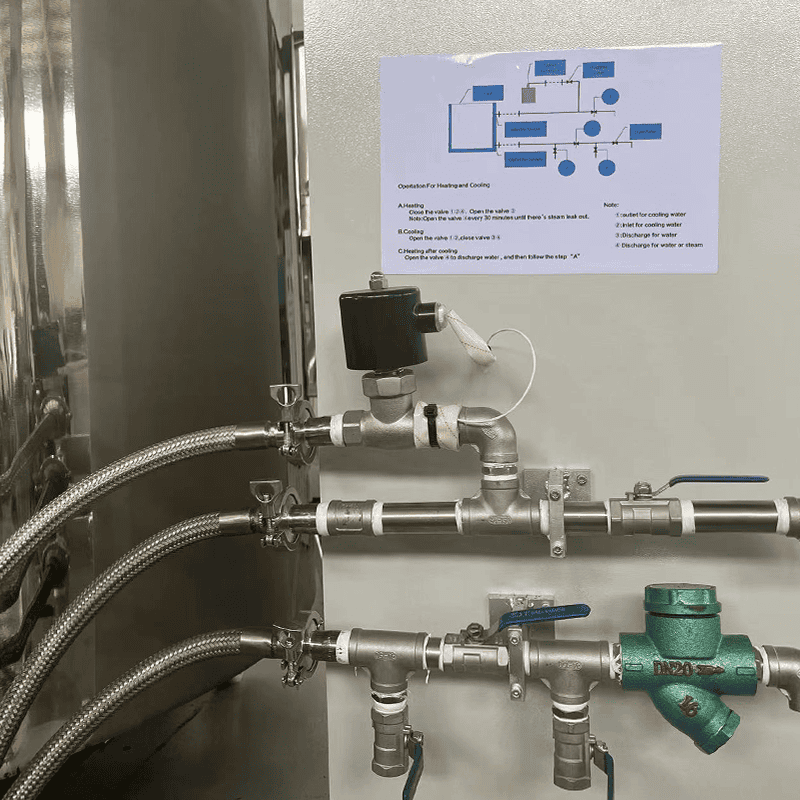

Water jacket for heating and cooling , heating conductive could be steam , hot water or conductive oil.

Ex-proof motor is optional.

Hydraulic press machine match the double planetary mixer.

Have a new project? Free talk to our experts.

Talk NowMaterial : both 304 ,316 or other coating are optional

Suitable for adhesive, sealant, MS polymer, Lithuim Battery slurry, solder paste with viscosity 10,0000~1,000,000cps.

Working capacity covers 300L 500L 1000L and 3000L

Extreme vacuum up to -0.1 MPA for efficient defoaming.

Hydraulic press machine for discharging is combined in one platform with the mixer.

Orisun Large Scale Industry Double Planetary Mixer Features

Suitable for adhesive, sealant, MS polymer, Lithuim Battery slurry, solder paste with viscosity 10,0000~1,000,000cps.

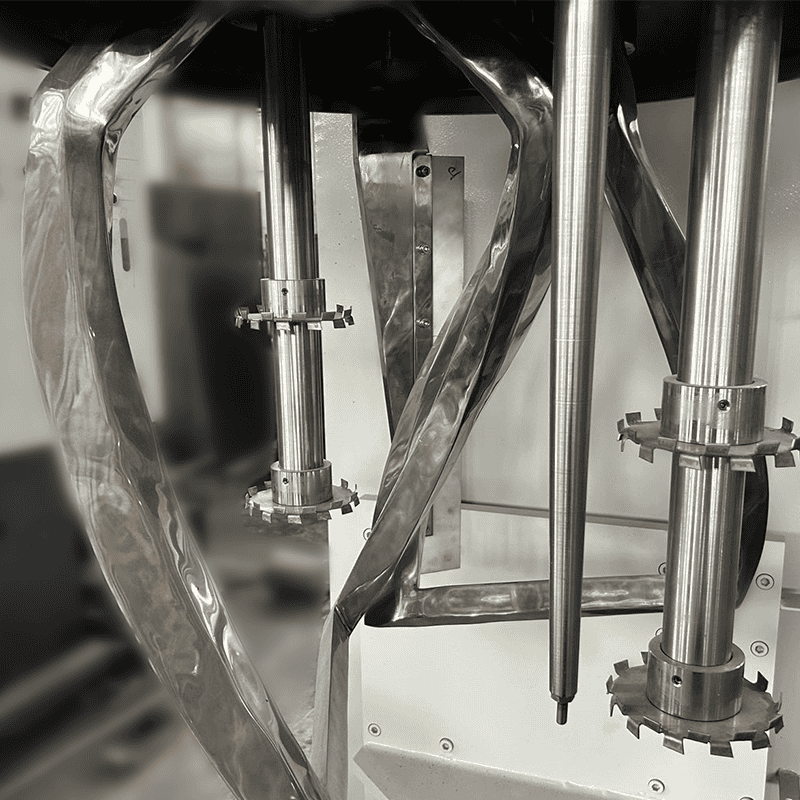

Double screw belt low speed mixing paddle is made of casting and polished, more solid and suitable for high viscosity materials.

high speed disperse is equipped for scatter powder in short time

Extreme vacuum up to -0.1 MPA for efficient defoaming.

Working capacity from 300L 500L 1000L 3000L

Scraping wall agitation fits the mixing tank design, ensuring no material sticking to the inner wall of the mixing tank.

Material 304 and 316 are optional.

Lifting and lowering is controlled by a hydraulic station.

<script>

// To enable code execution go to Bricks > Settings > Builder Access.

//You must also make sure "execute code block" is toggled on this Bricks code element.

const card = '.fr-feature-card-echo'

const featureCards = document.querySelectorAll(card);

for (var i = 0; i < featureCards.length; i++) {

const c = featureCards[i]

const textSelector = `${card}__text`

const cardText = c.querySelector(textSelector)

const heading = c.querySelector(`${card}__heading > a`)

const textHeight = cardText.offsetHeight;

cardText.style.height = '1px';

c.addEventListener('mouseover', function() {

this.querySelector(textSelector).style.height = textHeight + 'px';

this.querySelector(textSelector).style.opacity = '1';

});

c.addEventListener('mouseout', function() {

this.querySelector(textSelector).style.height = '1px';

this.querySelector(textSelector).style.opacity = '0';

});

heading.addEventListener('focus', function() {

c.querySelector(textSelector).style.height = textHeight + 'px';

c.querySelector(textSelector).style.opacity = '1';

});

heading.addEventListener('blur', function() {

c.querySelector(textSelector).style.height = '1px';

c.querySelector(textSelector).style.opacity = '0';

});

}

</script>SPECIFICATION

Lab Double Planetary Mixer Technical Data

Get specific information on the specifications and parameters of our equipment.

| Model | DPS-300 | DPS-500 | DPS-1000 | DPS-2000 |

| Size of Tank | Φ850*650 | Φ1000*830 | Φ1300*1000 | Φ1500*1300 |

| Design Volumn (L) | 376 | 650 | 1327 | 2300 |

| Working Volum (L) | 300 | 500 | 1000 | 2000 |

| Low speed mixing power (kw) | 22 | 37 | 45 | 75 |

| High speed disperse power (kw) | 30 | 45 | 55 | 90 |

| Revolution speed (rpm) | 0-28 | 0-24 | 0-20 | 0-13 |

| Rotation speed(rpm) | 0-56 | 0-48 | 0-40 | 0-35 |

| High speed disperse speed (rpm) | 0-1450 | 0-1450 | 0-1450 | 0-1450 |

| scraper speed(rpm) | 0-28 | 0-24 | 0-20 | 0-13 |

| Limit Vacum(Mpa) | -0.095 | -0.095 | -0.095 | -0.095 |

| Distance of lift(mm) | 750 | 900 | 1200 | 1500 |

| Hydraulic station power(kw) | 2.2 | 2.2 | 2.2 | 2.2 |

| Dimension mm(L*W*H) | 3300*1300*3400 | 3700*1500*3500 | 4200*1800*3780 | 4500*2010*4000 |

| Weight (KG) | 4500 | 6500 | 12000 | 16000 |

Trusted Globally in Key Industries

Areas of Application for Orisun Double Planetary Mixers

Our mixers deliver exceptional results in diverse industries worldwide.

Pharmaceutical Industry

Polymer Gel , Composite Resin , Ceramics GlassIonomer and other dental material.

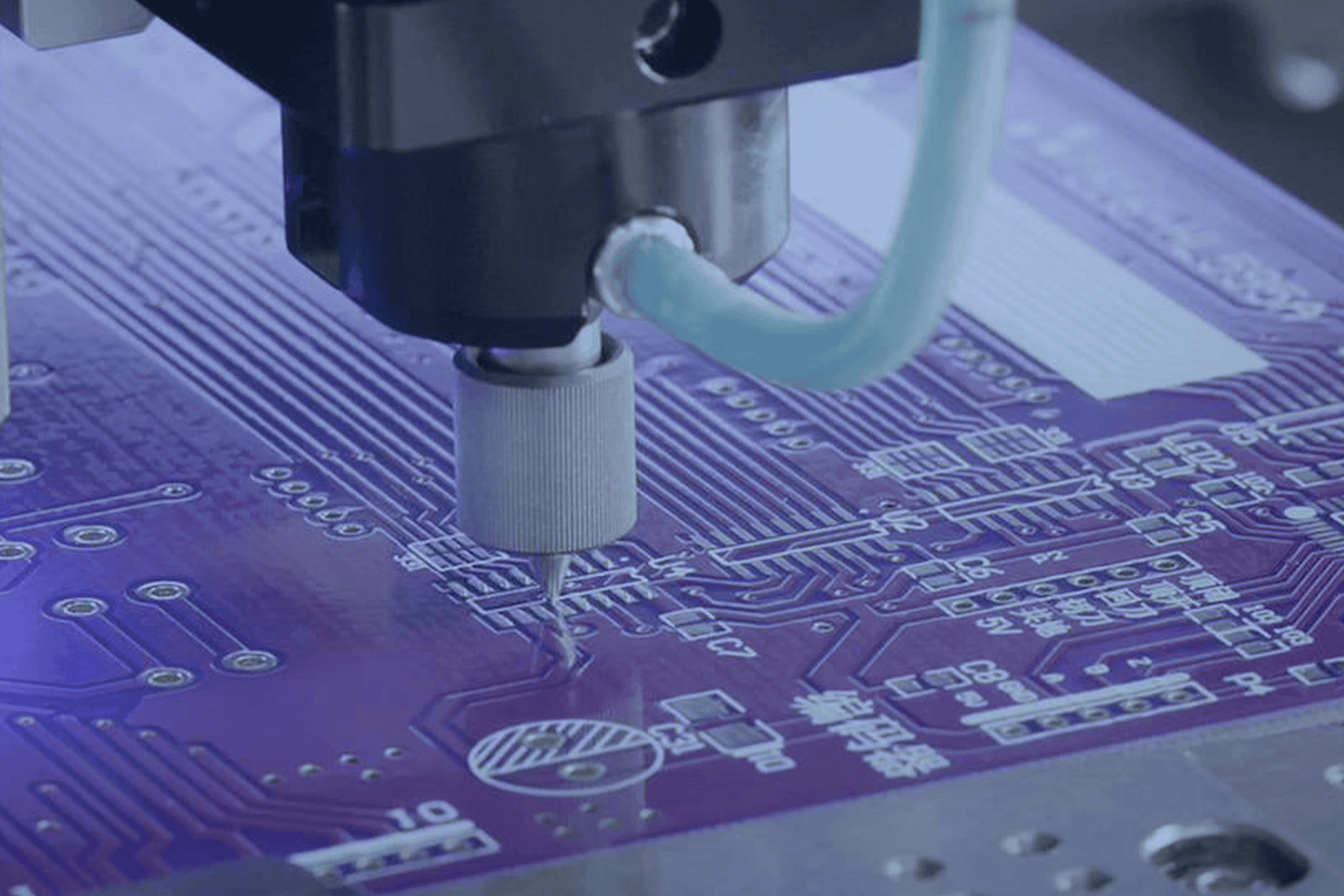

Electric Industry

Solder paste, ceramic slurry, magnetic materials, silicone ink, electronic adhesive, electronic and electrical device potting glue, hot melt adhesive.

New Energy

Graphene Paste, Battery slurry and paste (lithium batteries, nickel-chromium batteries, nickel-metal hydride batteries, fuel cells, power batteries, button batteries, etc).

Chemical Industry

sealants and adhesives (silicone sealant,MS Polymer, insulating glass sealant, waterproof sealant, anaerobic adhesive), Synthetic resin rubber, synthetic resin, various powder materials,filling paste.

Options and Structure of the Equipment

Orisun's mixer offer a range of equipment options and carefully designed configurations to meet the needs of different industries.

- The tank could be opened by lifting the cover or fall the tank .

- Bigger hopper for adding large quantity powder

- Different kinds of operation are optional , as PLC and button

- The Brands of electric parts could be adopt as customer recommend as Siemens , Schneider , ABB etc.

- Load cells as Mettler-Toledo and other brands are optional.

- Ex-proof (ATEX) for whole machine are optional

- Hydraulic press machine for discharging are optional

- High speed disperse mixing are optional

- Different kind of mixing paddle as screw paddle and multi-shaft are optional.

- Flow meter automation for feeding liquid oil and water;

- SIP is available upon request;

- Different power supply acceptable;

- Heating medium could be steam , water or conductive oil.

Contact a Mixing Equipment Specialist Now

Get our professional mixing equipment with one-stop customized solutions, we can provide expert support with fast response within 2 hours during working hours to solve your problems and meet your needs.

Talk Now!

Benefits of Choosing Orisun Large scale Double Planetary Mixer

The Orisun large scale double planetary mixer becomes a reliable choice for efficient powerful mixer for mass production high viscosity material .

Precise Mixing

The Orisun double planetary mixer is designed to provide precise and uniform mixing results. It employs a dual-agitator system with two planetary blades that rotate on their own axes while revolving around the center axis. This ensures thorough mixing and eliminates dead spots, resulting in consistent and homogenous mixing of ingredients.

High Efficiency

The mixer’s unique design maximizes the efficiency of mixing processes. The combination of planetary and rotational motions enables faster and more efficient blending, dispersing, and kneading of various materials. This allows for shorter mixing times and increased productivity in the lab.

Versatility

The Orisun double planetary mixer is highly versatile and can handle a wide range of applications. It is suitable for mixing various viscosities, from low to high, making it ideal for processing a diverse range of materials such as pastes, creams, gels, powders, and more. It is commonly used in industries such as pharmaceuticals, cosmetics, food, chemicals, and research laboratories.

Easy Operation and Maintenance

Orisun large scale double planetary mixers are designed with user friendly. They feature intuitive controls and interfaces, allowing for easy operation and monitoring of the mixing process. Additionally, these mixers are constructed with durable and easy-to-clean materials, facilitating quick and hassle-free maintenance.

Customization Options

Orisun understands that different mixing applications may have specific requirements. They offer customization options to tailor the lab double planetary mixer to your specific needs. From varying mixer sizes and capacities to adjustable mixing speeds and optional features, you can optimize the mixer’s performance for your unique mixing applications.

Scalability

If you require larger-scale production in the future, Orisun offers a range of industrial-scale double planetary mixers that share similar design principles and provide seamless scalability, ensuring continuity in your mixing processes.

{acf_how_does_it_work_how_does_it_work_subheading}

{acf_how_does_it_work_how_does_it_work_heading}

{acf_how_does_it_work_how_does_it_work_description}

Orisun large Scale Industry Double Planetary Mixer Customization Options

Orisun offers a range of customization options for their lab double planetary mixers to meet specific requirements and preferences.

Material of Construction

The mixer’s construction materials can be customized based on the compatibility requirements of your ingredients or the industry standards you need to adhere to. Options may include stainless steel, special alloys, or other corrosion-resistant materials.

Controls and Automation

Depending on your requirements, Orisun can customize the control system and level of automation for the mixer. This can include features like programmable recipes, touch-screen interfaces, data logging capabilities, and integration with other equipment or process control systems.

Mixing Blade Design

Depending on the characteristics of your materials and the desired mixing outcome, Orisun can customize the design of the planetary mixing blades. This includes variations in shape, size, and surface coatings to optimize the mixing efficiency and achieve the desired results.

Heating and Cooling Options

If your application requires precise temperature control, Orisun can incorporate heating and cooling options into the mixer design. This enables you to maintain the desired temperature throughout the mixing process, promoting efficient blending and ensuring product stability.

Mixing Equipment Expert

Why Choose Orisun

We aim to provide not just high-quality equipment, but also the service, support, and expertise you need to make your operation as efficient and successful as possible.

Quality and Performance

Orisun provides high-quality mixers, ensuring efficient and reliable performance for improved production and product quality.

Innovation and Customization

We offer innovative, customizable mixing solutions, tailored to meet your unique operational requirements and challenges.

Exceptional Service and Support

Orisun is committed to excellent customer service, offering comprehensive training and ongoing technical support for our products.

Safety and Compliance

Prioritizing safety, Orisun's mixers feature numerous safety measures and comply with all relevant industry standards and regulations.

From the First Consultation

Service and Support

Orisun is committed to offering extensive services and support to ensure the optimal performance of your high shear mixer.