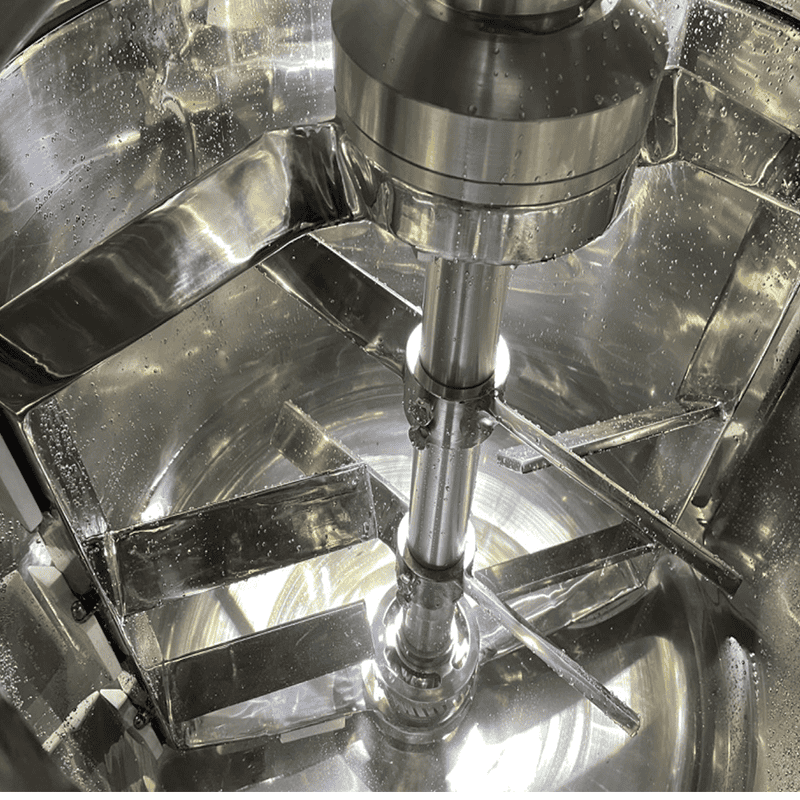

Vacuum Emulsifying Homogenizer

We are a professional vacuum emulsifying homogenizer supplier, with 22 years of practical experience, Orisun has the expertise and know-how to help you scale up from laboratory or pilot plant to full production.

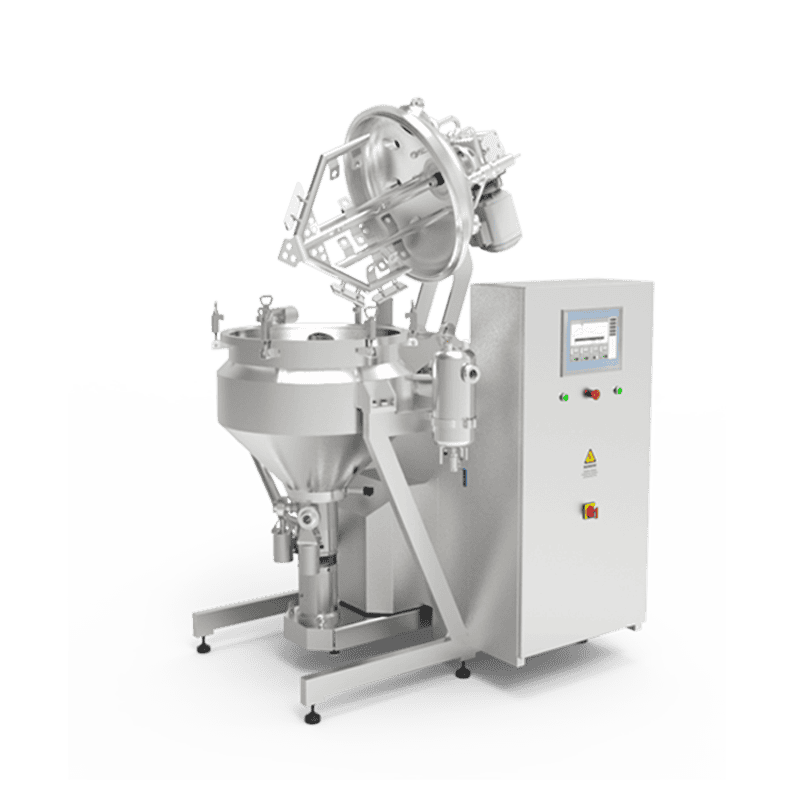

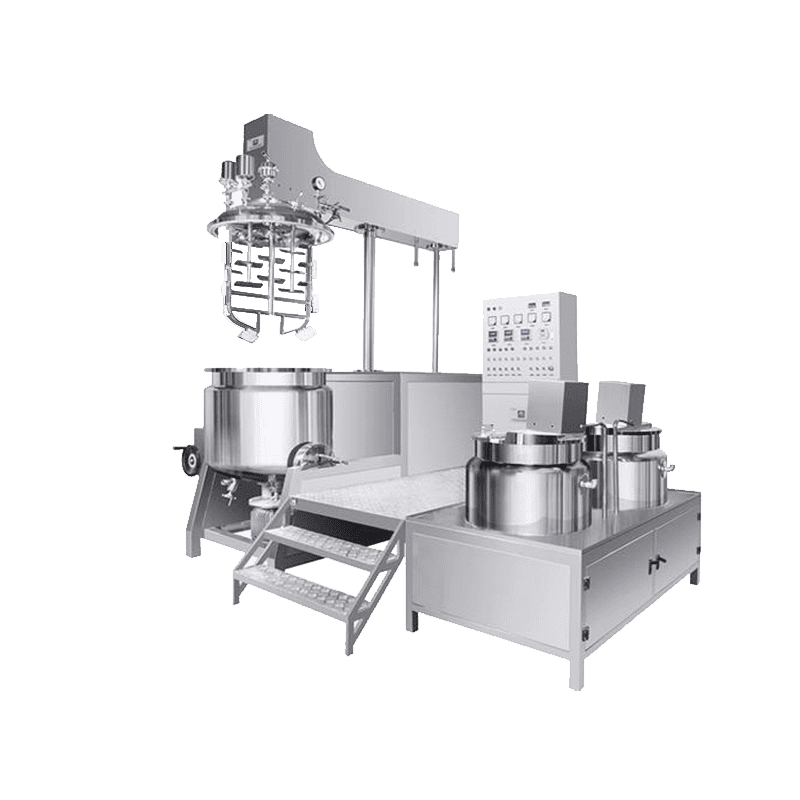

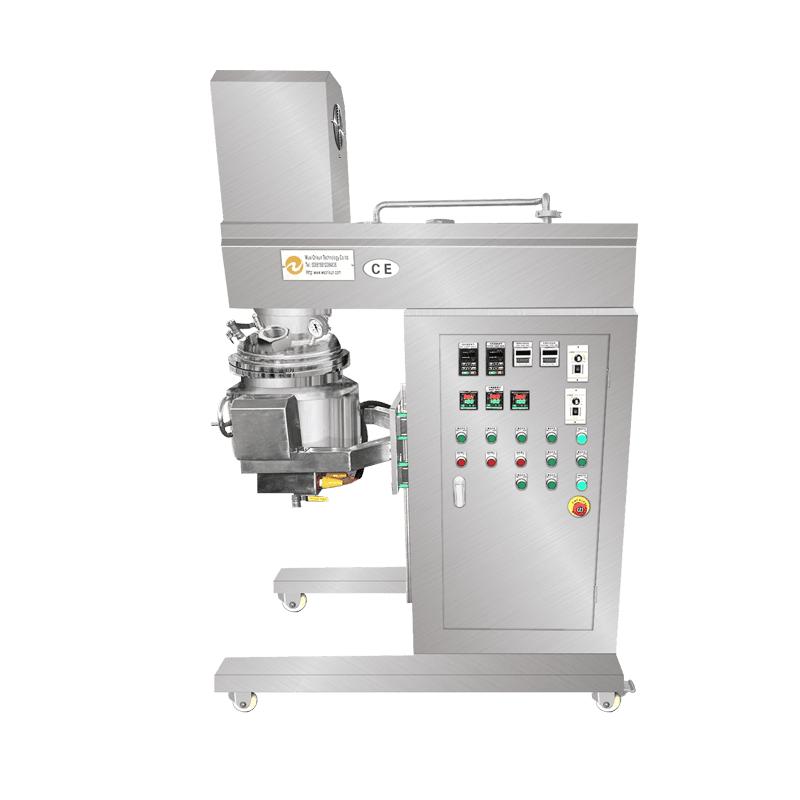

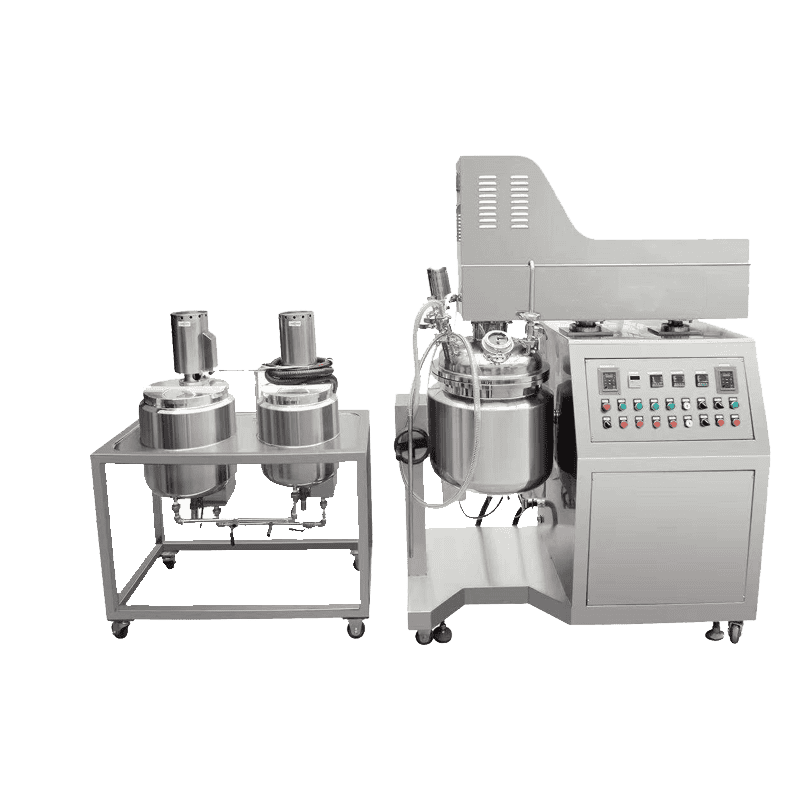

Our Vacuum Emulsifying Homogenizer Equipments

Orisun Vacuum Emulsifying Homogenizer

Our vacuum emulsifying homogenizer combine cutting-edge technology with superior design to deliver exceptional emulsification results.

Applicable to Various Industries

Application Field

Food and Beverage

In this industry, homogenizers and emulsifiers are used to improve texture, enhance flavor release, and prevent separation in products like sauces, dressings, dairy products, and beverages.

Pharmaceuticals

These tools are essential in the production of pharmaceutical creams, ointments, and suspensions, where consistent particle size and distribution are crucial for product performance. They are also used in the production of emulsified vaccines.

Cosmetics

Homogenizers and emulsifiers play a significant role in cosmetics manufacturing, creating products like lotions, creams, and makeup with a smooth, uniform consistency.

Chemicals

These tools are used to manufacture products like paints, emulsions, and adhesives, where it’s necessary to achieve a uniform dispersion of particles.

Vacuum Emulsifying Homogenizer Benefits

What Are the Benefits of Mixing with the Orisun Vacuum Emulsifying Homogenizer?

Orisun aims to provide equipment that increases the productivity and profitability of your business, while ensuring the creation of superior products.

Superior Product Quality

By reducing particle sizes to microscopic levels, Orisun homogenizers and emulsifiers ensure an exceptional consistency and stability in your products. This enhances the quality of your end products, whether in terms of texture, flavor, or appearance.

Versatility

Orisun homogenizers and emulsifiers are suitable for a variety of applications across several industries, making them a flexible choice for any business.

Enhanced Efficiency

With Orisun, you can achieve desired results faster and more efficiently. Our homogenizers and emulsifiers are designed to handle high-volume production without compromising on the quality of the output.

Reliable Performance

Built with durable materials and superior engineering, Orisun equipment guarantees reliable performance over a long operational life.

Scalable Solutions

Our equipment is designed to be scalable, meaning it can grow with your business. Whether you're a small lab or a large industrial plant, Orisun has solutions that can be tailored to your needs.

Customizable

We offer customization options to meet the specific needs of your production process. Whether you need special materials for corrosive materials or want to include additional features, Orisun can accommodate your needs.

Orisun aims to provide equipment that increases the productivity and profitability of your business, while ensuring the creation of superior products.

What Safety Measures Must Be Followed While Using a Vacuum Emulsifying Homogenizer?

- Training: Anyone operating a homogenizer emulsifier should be thoroughly trained in its use. They should understand the process, know how to operate the controls, and be aware of potential hazards.

- Protective Gear: Appropriate personal protective equipment (PPE) should be worn by all operators. This includes safety glasses, gloves, and possibly a lab coat, depending on the nature of the substances being processed. If the homogenizer emulsifier produces loud noise, ear protection may also be necessary.

- Maintenance and Inspection: Regular inspection and maintenance of the homogenizer emulsifier is crucial for safety. This ensures the machine is in good working order, prevents malfunctions, and extends its lifespan.

- Avoid Overloading: Operators should avoid overloading the equipment. Always adhere to the manufacturer’s guidelines regarding the maximum capacity to prevent any potential equipment failure or accidents.

- Guard Moving Parts: Ensure that the homogenizer emulsifier has guards in place to prevent contact with moving parts, especially the high-speed rotor.

- Clear Working Area: The area around the homogenizer emulsifier should be kept clear of unnecessary objects, tools, or materials to avoid accidents.

- Emergency Protocols: Operators should know the procedure to follow in case of an emergency, including how to quickly shut off the machine.

- Safe Handling of Materials: If handling hazardous materials, additional safety measures may be required, such as using a fume hood. Always check the Material Safety Data Sheets (MSDS) for any substances used.

- Secure Equipment: Ensure the machine is securely mounted or placed on a stable surface to prevent any movement during operation.

- Ventilation: Ensure the work area is well-ventilated, especially if volatile or potentially harmful substances are being processed.

Initial Contact

Reach out to our team via email, phone, or our website's contact form. Provide some basic information about your operation and your mixing needs.

Requirement Analysis

Our team will follow up with you to discuss your needs in more detail. This could involve questions about the materials you're working with, the volume of production, specific standards or regulations you need to comply with, and any other special requirements you may have.

Solution Proposal

Based on your needs, we will propose a suitable high shear mixer from our product range, or a custom solution if necessary. This proposal will include technical specifications, pricing, delivery times, and any other relevant information.

Negotiation and Agreement

We'll discuss the proposal with you, making any necessary adjustments based on your feedback. Once everything is agreed upon, we'll formalize the agreement with a contract.

Production and Delivery

After the contract is signed, we'll start manufacturing your mixer (if it's a standard product, it may already be in stock). Once it's ready, we'll arrange delivery and installation if applicable.

Training and Support

We provide comprehensive training for your team on how to operate and maintain the mixer safely and efficiently. Our support doesn't end after delivery; we're always available to answer questions, provide technical support, or help with any issues that might arise.

Mixing Equipment Expert

Why Choose Orisun

We aim to provide not just high-quality equipment, but also the service, support, and expertise you need to make your operation as efficient and successful as possible.

Quality and Performance

Orisun provides high-quality mixers, ensuring efficient and reliable performance for improved production and product quality.

Innovation and Customization

We offer innovative, customizable mixing solutions, tailored to meet your unique operational requirements and challenges.

Exceptional Service and Support

Orisun is committed to excellent customer service, offering comprehensive training and ongoing technical support for our products.

Safety and Compliance

Prioritizing safety, Orisun's mixers feature numerous safety measures and comply with all relevant industry standards and regulations.

From the First Consultation

Service and Support

Orisun is committed to offering extensive services and support to ensure the optimal performance of your high shear mixer.

FAQ

Frequently Asked Questions about Orisun Homogenizer Emulsifier, quick answers to your doubts.

Orisun homogenizer emulsifiers are versatile and suitable for various industries, including food and beverage, pharmaceuticals, cosmetics, chemicals, biotechnology, petroleum, and agriculture.

The capacity can vary based on the specific model of the homogenizer emulsifier. Orisun offers a range of models to meet different capacity needs, from small scale laboratory use to large scale industrial production.

Operators should be trained, wear appropriate PPE, perform regular maintenance, avoid overloading the equipment, guard moving parts, ensure the machine is securely placed, and follow all emergency protocols.

The Orisun homogenizer emulsifier is designed to produce highly stable emulsions, reducing the size of particles to the micro or nano scale. This ensures a uniform and stable mixture, enhancing product quality and shelf life.

Yes, Orisun equipment is built to comply with the highest industry standards and regulations. This ensures that your production process meets all necessary requirements.

Orisun is committed to providing excellent customer service. We offer comprehensive after-sales support, including troubleshooting, maintenance, spare parts, and user training.