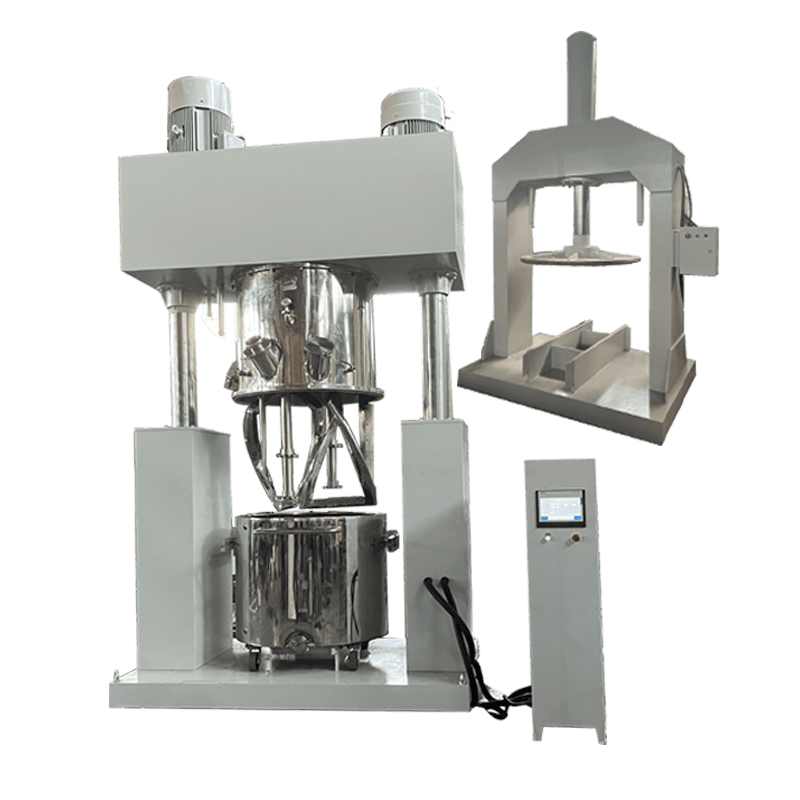

Industry Planetary Mixer

With the introduction of the double planetary mixer Orisun has quickly become the standard workhorse for high viscosity mixing throughout the process industry. With almost 20 years of practical experience Orisun has the expertise to meet the changing needs of the world.

Orisun Planetary Mixer

Our Planetary Mixer Equipments

Orisun pioneered a series of design and engineering improvements that expanded the capabilities and types of the original dual planetary mixer.

Ideal for Various Industries

Application Field

Pharmaceutical Industry

This double planetary mixer is welcomed in pharmaceutical industry for making hard and condensed dental material , high viscosity polymer Gel and other similar material

Electric Industry

With powerful motor and casting paddle , the double planetary mixer is ideal for manufacture solder paste , conductive glue, ceramic slurry, silicone ink ,etc .

New Energy Industry

Graphene Paste, Battery slurry and paste (lithium batteries, nickel-chromium batteries, nickel-metal hydride batteries, fuel cells, power batteries, button batteries, etc).

Chemical Industry

one of the most important application of double planetary mixer is for making high viscosity sealant and adhesive as silicone sealant , MS Polymer, insulating glass sealant, waterproof sealant, anaerobic adhesive), Synthetic resin rubber, synthetic resin, various powder materials,filling paste

Planetary Mixer Benefits

What Are the Benefits of Mixing with the Orisun Planetary Mixer?

Orisun planetary mixers bring several significant benefits to businesses across various industries.

Versatility

Orisun's planetary mixers can handle a wide range of materials, from liquids and pastes to powders and granules. This versatility makes them suitable for many different industries and applications.

Efficiency

Orisun mixers offer a high degree of efficiency due to their advanced mechanical design. The unique rotation and revolution mixing action reduces mixing times and improves productivity.

Customizable

We understand that different industries have different requirements. That's why Orisun mixers can be customized to fit specific needs, including options for different bowl capacities, mixing speeds, and attachments.

Consistency and Homogeneity

Our mixers ensure consistent and homogeneous mixing of all ingredients. This is crucial in industries such as food and beverage, pharmaceuticals, and cosmetics, where product consistency directly affects quality.

Eco-friendly

Our mixers are designed with energy-efficient motors to reduce energy consumption and minimize environmental impact.

Ease of Operation and Maintenance

Our planetary mixers are designed with user-friendly controls for ease of operation. Additionally, they're built for easy cleaning and maintenance to minimize downtime.

Orisun planetary mixers bring several significant benefits to businesses across various industries.

What Safety Measures Must Be Followed While Using a Planetary Mixers?

- Training: Ensure that all operators are adequately trained and understand how to use the mixer safely and correctly. They should be familiar with all of its functions and safety features.

- Protective Clothing: Operators should wear appropriate protective clothing, including gloves, safety glasses, and in some cases, dust masks or face shields. Loose clothing, ties, or jewelry should not be worn as these could get caught in the machinery.

- Inspection: Regularly inspect the mixer and its components for signs of wear or damage. Address any issues immediately to prevent accidents or malfunctions.

- Clear Workspace: Ensure the area around the mixer is clean and free of obstacles. This not only helps prevent accidents but also makes it easier to notice any leaks or spills.

- Safety Devices: Never bypass or disable any safety devices, such as guards or emergency stop buttons. These are designed to protect the operator and should always be in working order.

- Proper Shutdown: Always turn off and disconnect the mixer from the power supply before performing maintenance, cleaning, or changing attachments.

- Avoid Overloading: Do not exceed the mixer’s recommended capacity as it can cause the machine to overheat or fail.

Initial Contact

Reach out to our team via email, phone, or our website's contact form. Provide some basic information about your operation and your mixing needs.

Requirement Analysis

Our team will follow up with you to discuss your needs in more detail. This could involve questions about the materials you're working with, the volume of production, specific standards or regulations you need to comply with, and any other special requirements you may have.

Solution Proposal

Based on your needs, we will propose a suitable high shear mixer from our product range, or a custom solution if necessary. This proposal will include technical specifications, pricing, delivery times, and any other relevant information.

Negotiation and Agreement

We'll discuss the proposal with you, making any necessary adjustments based on your feedback. Once everything is agreed upon, we'll formalize the agreement with a contract.

Production and Delivery

After the contract is signed, we'll start manufacturing your mixer (if it's a standard product, it may already be in stock). Once it's ready, we'll arrange delivery and installation if applicable.

Training and Support

We provide comprehensive training for your team on how to operate and maintain the mixer safely and efficiently. Our support doesn't end after delivery; we're always available to answer questions, provide technical support, or help with any issues that might arise.

Mixing Equipment Expert

Why Choose Orisun

We aim to provide not just high-quality equipment, but also the service, support, and expertise you need to make your operation as efficient and successful as possible.

Quality and Performance

Orisun provides high-quality mixers, ensuring efficient and reliable performance for improved production and product quality.

Innovation and Customization

We offer innovative, customizable mixing solutions, tailored to meet your unique operational requirements and challenges.

Exceptional Service and Support

Orisun is committed to excellent customer service, offering comprehensive training and ongoing technical support for our products.

Safety and Compliance

Prioritizing safety, Orisun's mixers feature numerous safety measures and comply with all relevant industry standards and regulations.

From the First Consultation

Service and Support

Orisun is committed to offering extensive services and support to ensure the optimal performance of your high shear mixer.

FAQ

Frequently Asked Questions about Orisun Planetary Mixer, quick answers to your doubts.

Orisun planetary mixers are highly versatile and can handle a wide range of materials, including liquids, powders, pastes, and granules.

Orisun offers a variety of models with different capacities to suit different needs. Please consult the product specifications or reach out to our sales team for specific capacity information.

Orisun mixers are used across a variety of industries, including food and beverage, pharmaceuticals, cosmetics, chemical, construction, ceramics, plastics, and rubber. If you have specific requirements, our team can advise on the most suitable model.

Orisun planetary mixers are designed with energy-efficient motors to minimize energy consumption, reducing operating costs and environmental impact.

Regular maintenance involves routine cleaning after use and periodic checks of components for wear or damage. More detailed maintenance information can be found in the user manual.

Yes, Orisun provides options for customization, including different bowl capacities, mixing speeds, and attachments to suit your specific needs.

Orisun provides a comprehensive warranty for its mixers. The specific terms and duration of the warranty may vary, so please refer to your product documentation or contact our customer service team for detailed information.